ZJR Vacuum Emulsifying Mixer

Vacuum Emulsifying Mixer is suitable for the production of cosmetic cream, skin cream, eye cream, hair conditioner, hair dye cream, ointment, emulsification and ointment.

ZJR vacuum emulsifying mixers are the customizable equipment, which can be reasonably configured according to the customer’s specific requirements. Our homogenizers are suitable for the products that need to be emulsified and stirred in the vacuum state. The vacuum emulsifyer can be equipped with low-speed wall scraping and mixing for emulsion mixing of products with high viscosity. It also can be equipped with high shear emulsifying machine for the process of dispersion, emulsification, homogenization and mixing etc. Our vacuum emulsifying mixers can be equipped with these options: material preparing system, discharging system, cooling and heating temperature control system, vacuum system, PH online measurement control, CIP cleaning system, etc. Application range is wide, and the process is highly controllable. The complete set of vacuum homogenizer mixer includes main pot, water pot, oil pot, vacuum system, electric heating or steam heating temperature control system, electric control system etc. It is a specially designed equipment for producing cream, medicine ointment, emulsion and so on.

Working principle of vacuum emulsifying mixer

With the help of precise processing technology, and high cooperation between rotor and stator, high-speed rotation of powerful motor causes vacuum between rotor and stator, and materials are inhaled from the top and bottom of rotor and stator. The strong kinetic energy makes the rotor produce extremely high linear velocity, which makes the material fly out after strong impact, crushing, centrifugal extrusion, liquid layer friction and strong shearing between the clearance of rotor and stator, and generate strong turbulence under the action of various forces in different directions. The stable emulsion was produced by depolymerization, dispersion, homogenization, refinement and shearing of the material in a certain amount of emulsifier and mature process.

Features of vacuum emulsifying mixer

- The emulsification process of the main pot is carried out under the condition of full sealing, which prevents the pollution of dust and microorganism.

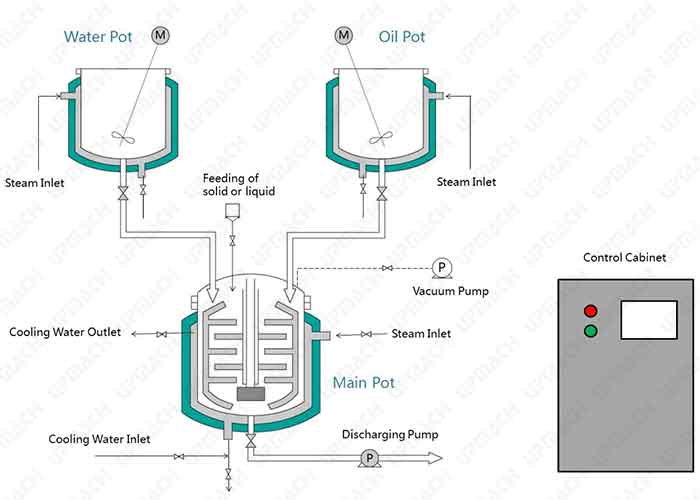

- The material in the water pot and oil pot are added to the main pot by means of vacuum feeding. The main pot can be heated or cooled.

- The material in the pot can be emulsified by high-speed internal circulation shear of homogenizer and can be mixed clockwise or counterclockwise. Clockwise mixing is frame scraping wall mixing and counterclockwise mixing is slurry mixing.

- The scraper agitator has centrifugal effect during operation, making the PTFE scraper cling to the wall of the pot, which can effectively solve the problem of material staining on the wall of the pot and no dead angle.

- The frequency conversion speed regulating device can adjust the speed steplessly.

- Homogeneous mixing and paddle mixing can be used separately or at the same time.

- Material dispersion, homogenization, emulsification and mixing can be completed in a short time.

- Homogeneous emulsification technology originally from Germany is specially designed for refined and homogeneous products. The vacuum emulsifying mixer can be equipped with wall scraping type or ribbon type and other types of agitation, so as to easily handle materials with viscosity of 1-300000 CPS.

- Real time measurement and control parts can easily control the temperature, pressure, pH value and other parameters.

- The main parts are made of international famous brands which are fine materials.

- The structure of Vacuum Emulsifying Mixer is brief and reasonable with simple operation.

- The design and technology of vacuum emulsifier are strictly met with GMP standards.

- Vacuum emulsifying mixers are the ideal machines for making cream, lotion, ointment and suppository.

Vacuum Emulsifying System Diagram

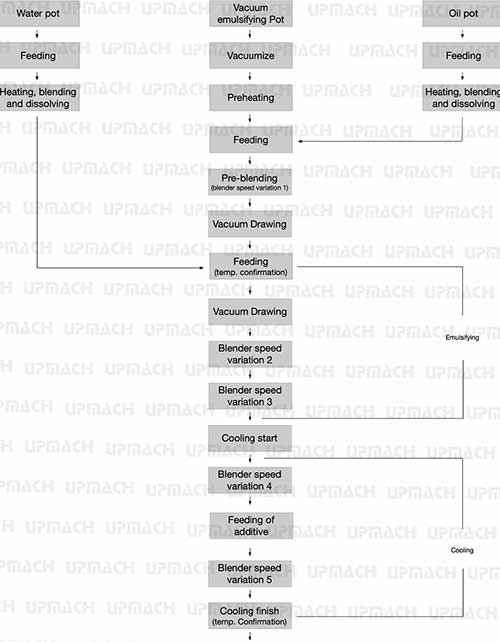

Technology process of vacuum emulsifying mixer

Bottom Vacuum Emulsifier

Model | 5A | 10A | 20A | 50A | 100A | 200A |

| Main Pot (L) | 5 | 10 | 20 | 50 | 100 | 200 |

| Water Pot (L) | 40 | 80 | 160 | |||

| Oil Pot (L) | 5 | 10 | 25 | 50 | 100 | |

| Wall scraping (KW) | 0.37 | 0.37 | 0.37 | 0.37 | 1.5 | 2.2 |

| Homogenizing (KW) | 0.75 | 0.22 | 2.2 | 4 | 4 | 7.5 |

| Water pot (KW) | 0.75 | 1.1 | 1.5 | |||

| Oil pot (KW) | 0.18 | 0.4 | 0.75 | 1.1 | 1.5 | |

| Hydraulic lifting (KW) | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | |

| Tilting (KW) | 0.75 | 0.75 | 0.75 | |||

| Vacuum Pump (KW) | 0.25 | 0.25 | 0.25 | 0.81 | 1.45 | 2.35 |

Model | 300A | 500A | 1000A | 2000A |

| Main Pot (L) | 300 | 500 | 1000 | 2000 |

| Water Pot (L) | 240 | 400 | 800 | 1600 |

| Oil Pot (L) | 150 | 250 | 500 | 1000 |

| Wall scraping (KW) | 3 | 4 | 7.5 | 11 |

| Homogenizing (KW) | 7.5 | 11 | 15 | 18.5 |

| Water pot (KW) | 2.2 | 2.2 | 4 | 5.5 |

| Oil pot (KW) | 1.5 | 2.2 | 3 | 5.5 |

| Hydraulic lifting (KW) | 1.5 | 1.5 | 2.2 | 2.2 |

| Tilting (KW) | 0.75 | 0.75 | 0.75 | 0.75 |

| Vacuum Pump (KW) | 2.35 | 2.35 | 3.85 | 5.5 |

Top Vacuum Emulsifier

Model | 5A | 10A | 20A | 50A | 100A | 200A |

| Main Pot (L) | 5 | 10 | 20 | 50 | 100 | 200 |

| Water Pot (L) | 40 | 80 | 160 | |||

| Oil Pot (L) | 5 | 10 | 25 | 50 | 100 | |

| Wall scraping (KW) | 0.37 | 0.37 | 0.37 | 0.37 | 1.5 | 2.2 |

| Homogenizing (KW) | 0.75 | 0.22 | 2.2 | 4 | 4 | 7.5 |

| Water pot (KW) | 0.75 | 1.1 | 1.5 | |||

| Oil pot (KW) | 0.18 | 0.4 | 0.75 | 1.1 | 1.5 | |

| Hydraulic lifting (KW) | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | |

| Tilting (KW) | 0.75 | 0.75 | 0.75 | |||

| Vacuum Pump (KW) | 0.25 | 0.25 | 0.25 | 0.81 | 1.45 | 2.35 |

Model | 300A | 500A | 1000A | 2000A |

| Main Pot (L) | 300 | 500 | 1000 | 2000 |

| Water Pot (L) | 240 | 400 | 800 | 1600 |

| Oil Pot (L) | 150 | 250 | 500 | 1000 |

| Wall scraping (KW) | 3 | 4 | 7.5 | 11 |

| Homogenizing (KW) | 7.5 | 11 | 15 | 18.5 |

| Water pot (KW) | 2.2 | 2.2 | 4 | 5.5 |

| Oil pot (KW) | 1.5 | 2.2 | 3 | 5.5 |

| Hydraulic lifting (KW) | 1.5 | 1.5 | 2.2 | 2.2 |

| Tilting (KW) | 0.75 | 0.75 | 0.75 | 0.75 |

| Vacuum Pump (KW) | 2.35 | 2.35 | 3.85 | 5.5 |

External Circulation Vacuum Emulsifier

| Model (ZJR) | 10C | 20C | 50C | 100C | 200C |

| Main Pot (L) | 10 | 20 | 50 | 100 | 200 |

| Water Pot (L) | 40 | 80 | 160 | ||

| Oil Pot (L) | 5 | 10 | 25 | 50 | 100 |

| Wall scraping (KW) | 0.37 | 0.37 | 0.37 | 1.5 | 2.2 |

| Homogenizing (KW) | 0.22 | 2.2 | 4 | 7.5 | 7.5 |

| Water pot (KW) | 0.75 | 1.1 | 1.5 | ||

| Oil pot (KW) | 0.18 | 0.4 | 0.75 | 1.1 | 1.5 |

| Hydraulic lifting (KW) | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 |

| Tilting (KW) | |||||

| Vacuum Pump (KW) | 0.25 | 0.25 | 0.81 | 1.45 | 2.35 |

Model | 300C | 500C | 1000C | 2000C | 3000C |

Main Pot (L) | 300 | 500 | 1000 | 2000 | 3000 |

Water Pot (L) | 240 | 400 | 800 | 1600 | 2400 |

Oil Pot (L) | 150 | 250 | 500 | 1000 | 1500 |

Wall scraping (KW) | 3 | 4 | 7.5 | 11 | 15 |

Homogenizing (KW) | 11 | 11 | 18.5 | 22 | 30 |

Water pot (KW) | 2.2 | 2.2 | 4 | 5.5 | 7.5 |

Oil pot (KW) | 1.5 | 2.2 | 3 | 5.5 | 7.5 |

Hydraulic lifting (KW) | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 |

Tilting (KW) |

|

|

|

|

|

Vacuum Pump (KW) | 2.35 | 2.35 | 3.85 | 5.5 | 7.5 |

Vacuum Emulsifier Homogenizer Photos