Sachet Packing Machine

Sachet packing machine can pack powder, granule, liquid, paste, cream, tablet/pill, softgel, pieces, card and other materials into small packages with three-side, four-side seal or fin seal etc.

DXD series can automatically finish the complete processes of sachet forming, dosing, filling, sealing, cutting, code printing, counting and photoelectric tracing, etc. The machines adopt different dosing systems to meet different packing demands which are in accordance with the national measurement standard.

These packing machines feature exquisite and favorable appearance and independent sealing. All the parts that touch the materials are made of high-quality stainless steel or corrosion-proof and poison-free plastic, which accords with the packing requirements for food and pharmaceutical industry. After decades of manufacturing and improvements, the function and performance are more stable and approaching perfect and are well-applied in the food, chemical, pharmaceutical and light industries.

Vertical Form Fill Seal Machine Features

- Big HMI interface, easy to operate.

- Numerical Controlled bag length, user friendly and accurate forming size.

- One button sets eye mark tracing; self-monitor errors; high precision eye mark positioning; lower manufacture cost.

- Smart control. When machine stops, Thermal Sealers stay open.

- Either under eye mark tracing mode or set-length mode, broken film can be sensed and automatically stops the machine.

- Error-tolerant technology under eye mark tracing mode, one or two eye marks missing doesn’t affect packing process.

- Batch control, convenient for bulk packing.

- The bag-pulling motor can work separately without starting the clutches.

- Thermal Sealers can be controlled separately, easy for testing.

- Optional English or Chinese language interface.

- Neat arranged Electric Control Box.

- All input and output status are HMI displayed, easy to operate and maintain.

- Sachet former vibration (front vibration) can be set by software, saving one Proximity Switch.

- Data auto saved.

Recommended Packing Material and temperature range

- Paper/PE, Aluminum Foil/PE, Nylon/PE Around 180℃

- Cellophane/PE Around 170℃

- Polyester Fiber/PE, BOPP/PE Around 160℃

- Polypropylene/PE Around 150℃

* If the packing material is not listed above, please test it to get the suitable sealing temperature.

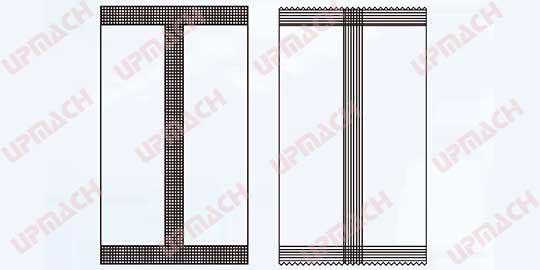

VFFS Sachet Style

3-side seal

4-side seal

Fin seal

Fin seal with die cut

Stick bag

Tetrahedron

Sachet powder packing machine

DXDF240

Dosing method: auger

Filling range: 0 - 100ml

Capacity: 40-70 sachets/min

Seal: 3-side or 4-side

More Details

Zigzag cut or straight cut

DXDF300

Dosing method: auger

Filling range: 0 - 350ml

Capacity: 40-70 sachets/min

Seal: 3-side or 4-side

More Details

Zigzag cut or straight cut

Granule packing machine

DXDK240

Dosing method: cup

Filling range: 1 - 80ml

Capacity: 40-100 sachets/min

Seal: 3-side or 4-side

More Details

Zigzag cut or straight cut

DXDK300

Dosing method: cup

Filling range: 1-330ml

Capacity: 40-100 sachets/min

Seal: 3-side or 4-side

More Details

Zigzag cut or straight cut

Liquid sachet packing machine

DXDL240

Dosing method: piston pump or needle valve pump

Filling range: 0-100ml

Capacity: 40-70 sachets/min

Seal: 3-side or 4-side

More Details

Zigzag cut or straight cut

DXDL300

Dosing method: piston pump or needle valve pump

Filling range: 0-100ml

Capacity: 40-70 sachets/min

Seal: 3-side or 4-side

More Details

Zigzag cut or straight cut

Tablet Capsule Softgel sachet packing machine

DXDP240

Dosing method: piece counting (vibration disc)

Filling range: customizable

Capacity: 40-60 sachets/min

Seal: 3-side or 4-side

More Details

Zigzag cut or straight cut

DXDP300

Dosing method: piece counting (vibration disc)

Filling range: customizable

Capacity: 40-70 sachets/min

Seal: 3-side or 4-side

More Details

Zigzag cut or straight cut